Comparing with other metal products, Wellter grating has the following advantages:

* Excellent quality at reasonable price.

* Light weight & high strength.

* Good ventilation.

* Good aesthetic appearance.

* Efficient stacking & delivery.

* Easy installation.

* Solid & durable.

Grating is dimensioned as per designed drawings. Prior to packing and delivery, it should be banded first, and then hot-dip galvanized or treated otherwise. Processing flow chart of grating is shown as below.

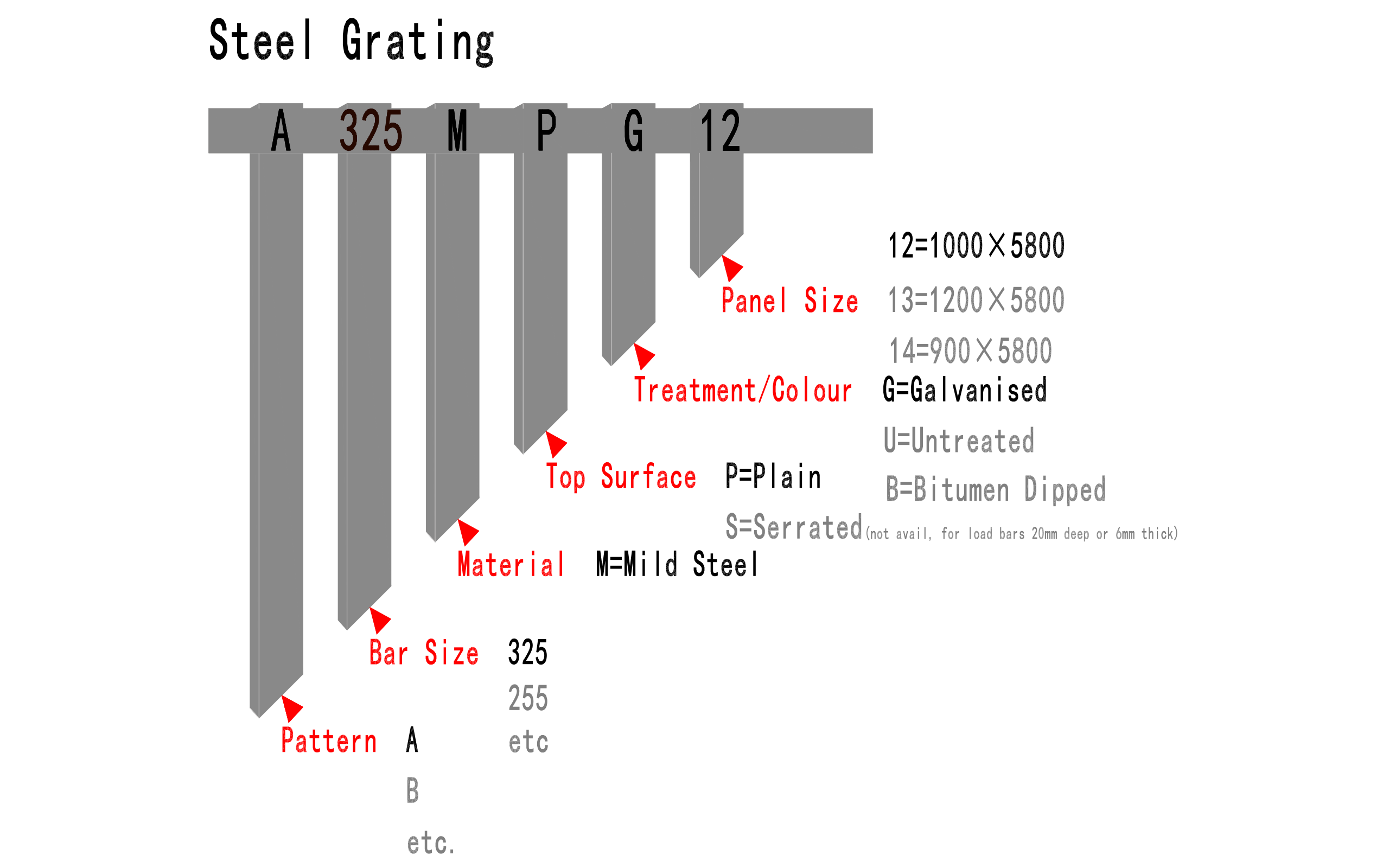

Cross Rod Pitch:

A 100 mm (center distance)

B 50 mm (center distance)

C 25 mm (center distance)

Cross Rod Size:

Generally 6 x 6 mm twisted rod

5 x 5 mm twisted rod for small size grating

5 x 5 mm round rod for stainless steel grating

Load Bar Size:

Usually 20 x 3 mm ~ 130 x 7 mm

Load Bar Pitch:

Series 1 30 mm (center distance)

Series 2 40 mm (center distance)

Series 3 40 mm (center distance)

Load Bar Top Surface:

P refers to common plain type

S refers to reinforced anti-skid serrated type

I refers to load bar with I- shape section

Surface Treatment:

G refers to hot- dip galvanizing

P refers to dip painting

U refers to no surface treatment

E refers to electrochemical polishing

Standard grating comprises Plain (P) square edge flat bars. To increase the slip resistance, Serrated (S) grating can be specified. Stainless Steel, 6mm bars, and any load bars 20mm deep will not be serrated normally.

.

Series 1 : This series is most commonly used throughout all sections of industry. Center pitch of load bars is 30mm. It is in accordance with USA standards, Australia standards and Japanese standards applicable etc. With highest density of flat bars and strength, it is suitable for different applications.

Series 2: This series is most economical and light. Center pitch of load bars is 40mm. It conforms to the requirement of Fixed Platform, Walkway, Stairway and Tread as regulated in British, Germany, France and Japanese standards etc. Its general applications include conveyor walkway, storage shelves, mezzanine floor, catwalk, security grilles and sun screens etc.

Series 3 :This series has been specifically developed for mining industry and used for hang ceiling. Center pitch of load bars is 60mm. The large square opening allows most materials to fall through the grating, thus keeping the walking surface clear and safe. This product is frequently specified for mining and mineral processing projects. With a high cost efficiency, it is the optimal choice for Hang Ceiling.

Grating : Chinese YB/T 4001 - 2007

Steel Material: Chinese GB 700 - 88, GB 1220- 92;

Hot-dip Galvanizing: Chinese GB/T 13912 - 2002

Note: Products can also be manufactured according to other standard as agreed by both parties (Buyer and Seller).

Besides specifications recommended below, other specifications are also available for design and manufacturing, which will depend on the quantity and delivery schedule requested. All details should be indicated in the contract after agreement of both parties. For relevant duty parameters of stainless steel grating, please refer to "Loads and Deflections Table of Carbon Steel Grating".